The material

Ultra-Low Density: With a density of less than 20 mg/cm³, our material is among the lightest in existence, making it ideal for applications where weight reduction is critical, such as aerospace, robotics, and high-performance equipment. For comparison, water’s density is 1 g/cm³—our material is nearly 50 times lighter.

Exceptional Porosity: Its highly porous structure provides an enormous internal surface area, crucial for processes like filtration, catalysis, and energy storage. Unlike active charcoal, this vast surface area is readily accessible to liquids, ensuring more efficient interaction and performance in various applications.

Thermal Stability and Fire Resistance: The material retains its structural integrity under extreme heat, making it suitable for high-temperature environments and fire-resistant applications.

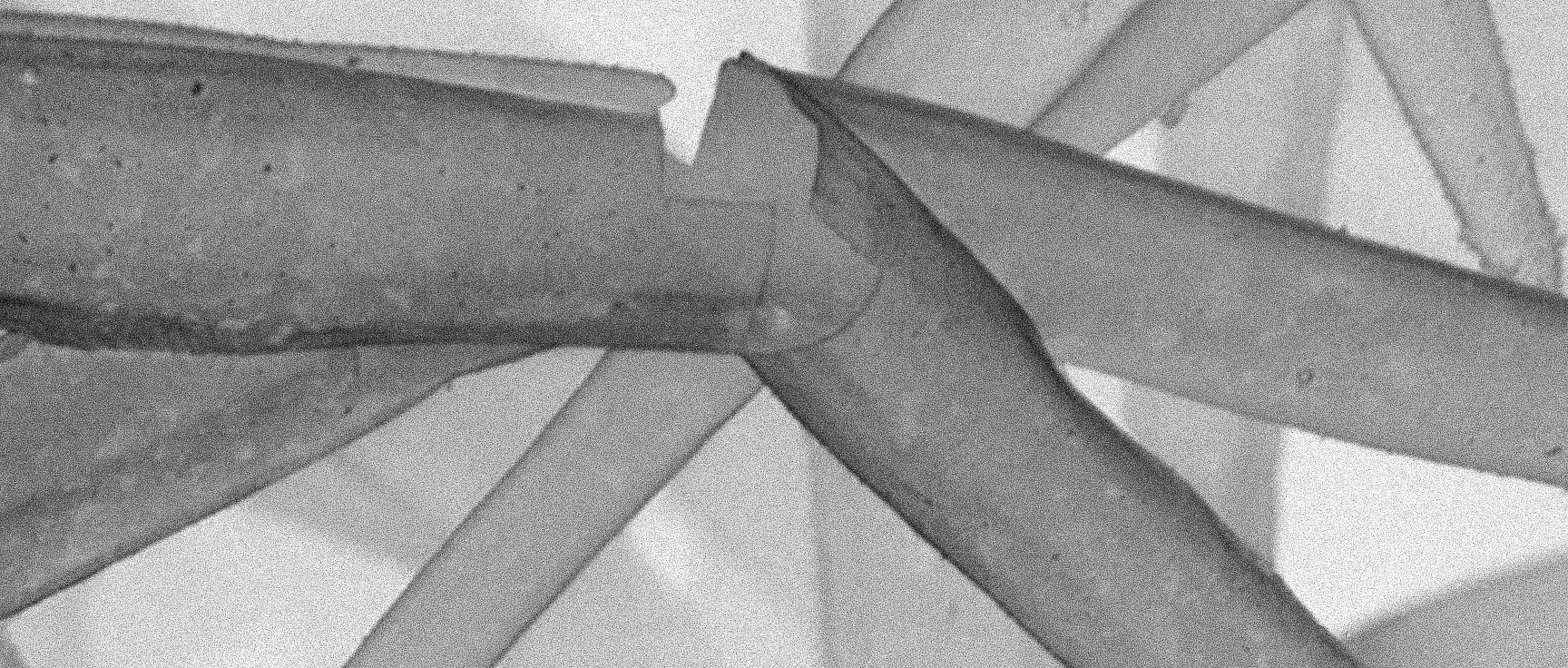

Nanostructured Framework: Constructed from interconnected hollow microtubes, the material combines lightweight properties with exceptional mechanical strength and flexibility.

Applications

Our material’s exceptional properties unlock a wide range of applications:

Actuation: Ideal for pneumatic systems, replacing traditional pneumatics while leveraging air expansion for acoustic or mechanical purposes.

Filtration: With self-cleaning and sterilization capabilities, it revolutionizes filtration systems for air and liquids, enhancing efficiency and sustainability.

Optics: Optimized for energy-efficient lighting and precise light diffusion, it enables advancements in laser and LED technologies.

Shielding: Ultra-lightweight and fire-resistant, it provides effective electromagnetic shielding, critical for aerospace and sensitive technologies.

We are driven by a commitment to innovation and excellence, working at the intersection of science and industry to create materials that address the challenges of today and opportunities of tomorrow. Join us on this journey to shape the future with material solutions that inspire and empower.

Production Process

The material is crafted through a multi-step, precision-engineered process. Starting with the creation of a robust template, this is coated with advanced nanomaterial dispersions before the template is etched away, leaving behind a highly functional lightweight structure. This process allows for scalable production without compromising quality, enabling broad adoption across industries.